Production managers are primarily responsible for planning processes. The system takes a lot of work off your hands with AI-powered sales and inventory forecasting. This forecasts potential sales based on historical data, providing an overview of expected demand and anticipated stockouts.

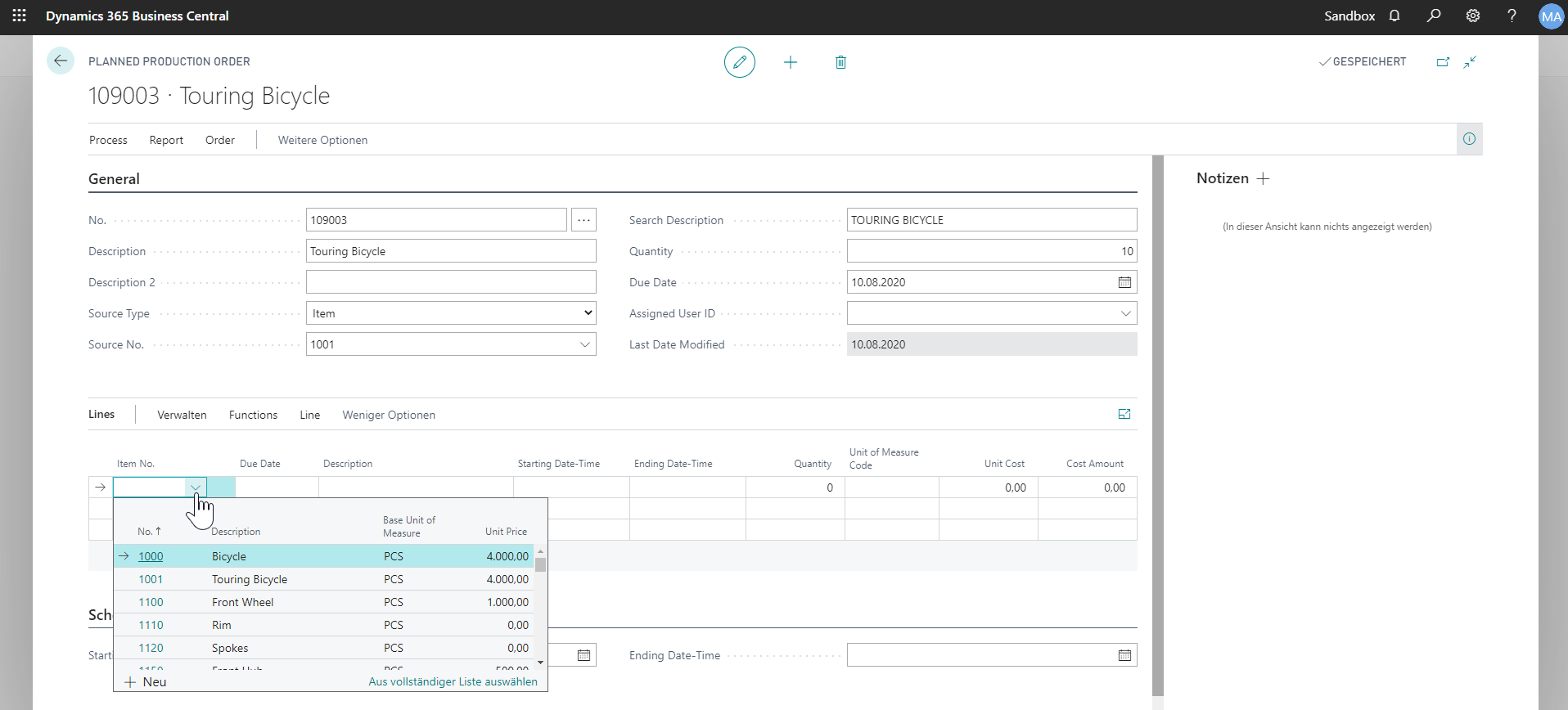

Production and material requirements planning

Using the Calculate Regeneration function, production and material requirements can be calculated based on actual and planned demand. Both production program planning and net requirements can be calculated separately or simultaneously.

Material requirements planning/net requirements

Material requirements planning forecasts the material needs for components based on actual demand. The main purpose of net requirements planning is to schedule formal plans for each item to provide the right item at the right time, in the right place, and in the right quantity.

Production program planning

Production program planning is the calculation of a production plan based on actual demand and sales planning. The calculation of the production program planning is performed for finished items with a plan or a sales order line. These items are referred to as “production program planning items” and are marked as dynamic when the calculation is started.

The visual representation of your planning can be expanded with various add-ons such as the Netronic Visual (Advanced) Production Scheduler.

Outsourcing

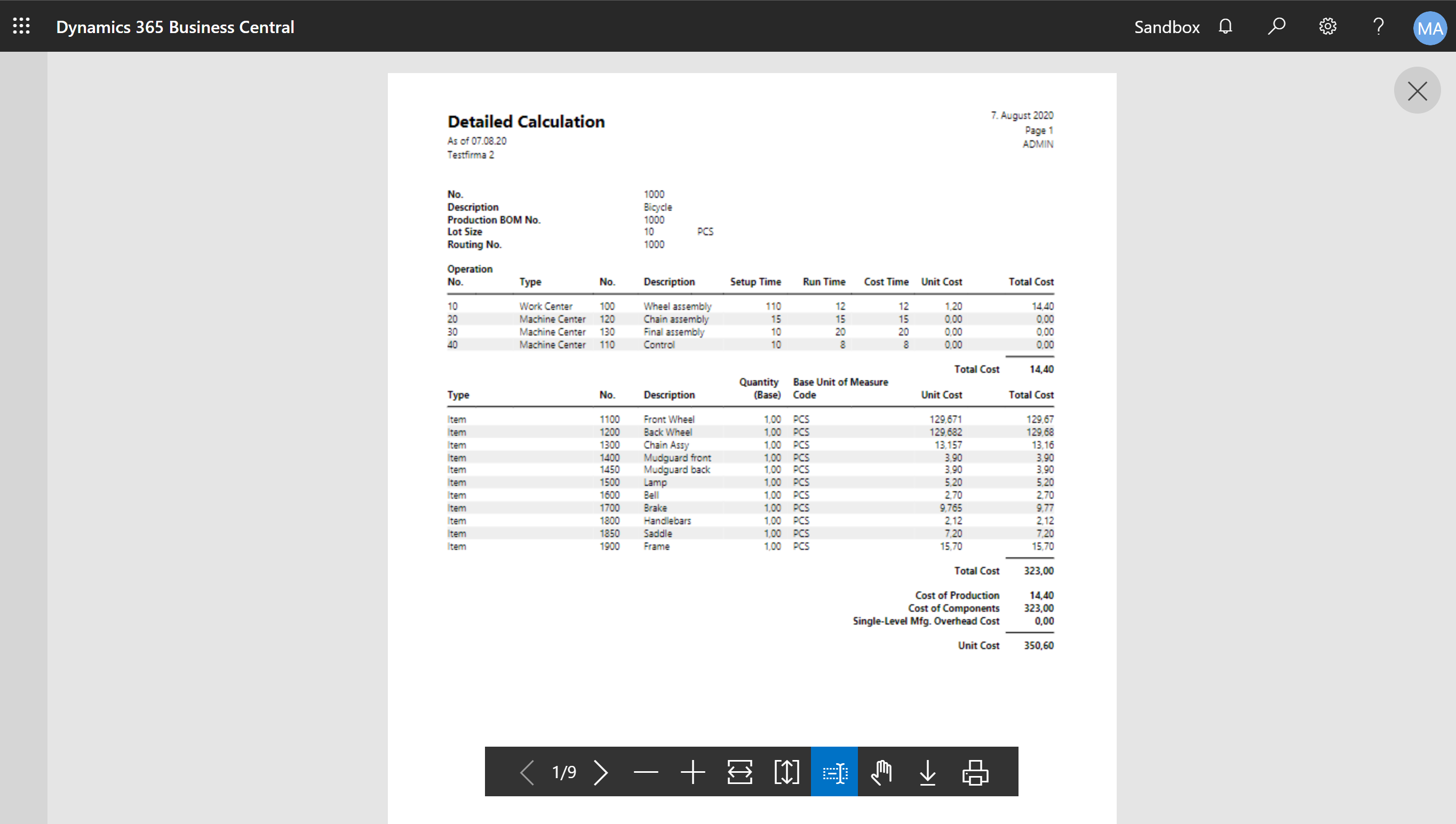

Outsourcing selected operations to vendors is common in many manufacturing companies. Outsourcing is realized through special work center groups assigned to vendors. The software recognizes the need for subcontracting, which can be created through the subcontracting proposal. Service costs can be added to the cost of production through this process.

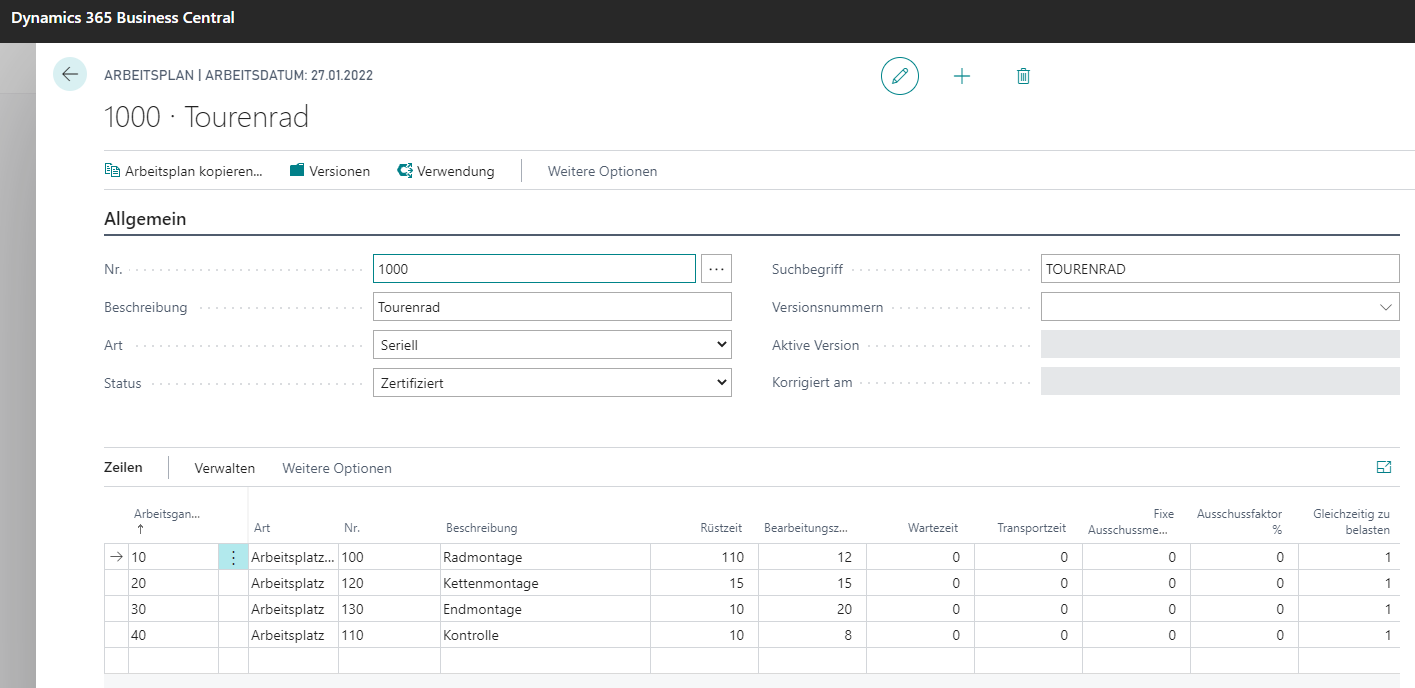

Bills of materials

With bills of materials (production or assembly bills of materials), you structure higher-level products consisting of individual components.

loading="eager" alt="Produktion-Montage">

loading="eager" alt="Produktion-Montage">